Use of standard solutions prepared manually is, due to its precision and reproducibility, widely used for instrument calibration. While manual, serial dilution of standard stock solution is practical in a laboratory setting, for instruments used in field, or deployed at remote location, an automated calibration using a single (stock) standard solution is desirable. In the Sequential Injection format, there are three ways how to accomplish this goal:

By serial dilution, by exploiting concentration gradient formed from the injected sample zone or by parsing the reaction rate curve. The gradient calibration is performed in SHC mode and is faster, the reaction rate calibration slower but more selective since it is performed in SFC mode.

Single Standard Calibration

Principles

2.2.38.A.

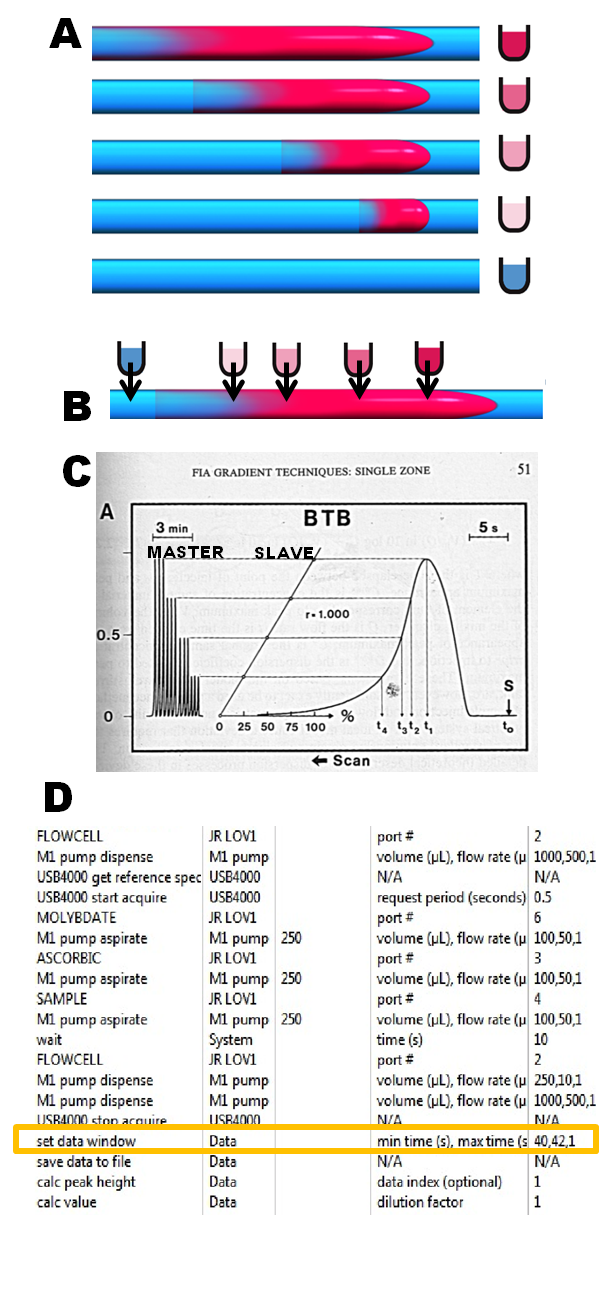

Serial dilution (A) is based on repetitive injection of decreasing volumes of standard solution that will by diluted by dispersion within the carrier stream on the way to detector. Over 40 FIA based publications utilizing this approach for calibration of FAA or ICP instruments are found in Hansen’s Bibliography, including the recently developed complementary dilution method (Koscielniak 2011, Kozak 2008)

The single standard gradient calibration technique (SSGC) exploits concentration-time profile generated by a single standard solution (Ruzicka & Hansen 1988). The single standard calibration curve (SLAVE) is obtained by using the calibration curve obtained by analyzing serial diluted standards (MASTER) to measure the virtual concentrations within the selected sections of the dispersed sample zone (B, C). This is done by a software protocol (D) that uses MASTER calibration and series of widows (orange box) to collect absorbance and virtual concentration values spaced along the tail section of the concentration gradient. In this way only a single (most concentrated) standard solution needs to be analyzed to obtain SLAVE calibration. Ahead of its time, SSGC technique was not reproducible enough, when used with then available technology (Sperling 1991). However, at long last, reproducible microfluidic manipulations combined with advanced data harvesting makes SSGC feasible.

P. Koscielniak et.al. Anal. Letters. 2011, 44:1-3,398

J. Kozak et.al., Talanta 2008, 77,587.

J. Ruzicka E.H.Hansen, “Flow Injection Analysis" 2nd Ed. p.51, NY. 1988

M.Sperling Z.Fang and B. Weltz, Anal. Chem. 1991, 63, 151..